Top Interview Question - Maintenance Procedure of Centrifugal Pump

Overhauling Procedure of Centrifugal Pump

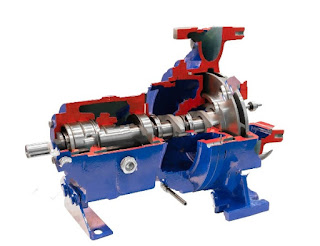

Hello guys,Here we will learn about how to overhaling back pull out centrifugal pump or we can say that the procedure of centrifugal pump maintenance.This is most common but most important topics ever for interview as well as skill devlopment purpose.

before going on main topic let start with basic part of centrifugal pump,

Rotory Parts,

1. Shaft 2. Impeller 3. Coupling 4. Mechanical seal 5. Oil rings, 6. Oil Deflector

Stationary Parts,

1. Casing 2. Stuffing box 3. Bearing Housing 4. Gland plate 5. Bearings Covers 6. Wear rings 7. Throat bush

Overhauling Steps :-

- Remove coupling gaurds after getting clearance of safety aspects like electrical isolation, Process line drainage etc.

- Remove coupling spacer and loose the casing bolts connected to stuffing box frame after removing and draining oil level glass and lube oil from bearing housing.

- Remove all connecting piping like mechanical seal line ,quench line,bearing housing coolinf water line,stufing box jacketing line etc.

- Pullouts back the pump from casing with care of casing gasket.

- Dismentle all parts from the pump unit as impeller,mechanical seal assembly,shaft sleeve,bearings,coupling hub etc.

- The following factors should be checked and recorded for further to estimate the performance condition of the pump are

- Wear ring clearance

- Seal setting compresssion

- Impeller diameter.

- shaft deflection.

- Axial thrust of shaft before removal

- Thruness of shaft at verious step

- Proper tracing of parts need to any vision able damage like crack,score,break etc

- Best is changing new one comparing reconditioning of parts.

- Assemble is the reversing procedure of dismentling as before seen.

- Before coupled alignment should be checked or corrected.

- Add or remove shims behind the stuffing box.

- Changing the position of the rotor depends clearance if possible.

- Machining of impeller hub if there is no another way.

|

|

|||

Comments

Post a Comment